How to make spraying drone route planning

When planning the spraying drone route planning, we need to set up a reasonable route according to the specific conditions of the site. Here are some route planning techniques for you, which can improve your flight defense capabilities.

Boundary retraction route planning

1 When there is an obstacle, the boundary is retracted by a distance.

When there is an obstacle, a certain safety distance is required to avoid accidental collision of the plant protection aircraft into the obstacle during the automatic flight. Assuming that the spray width of the plant protection machine is 5 meters, now whether the safety distance is reserved for 1 meter or 5 meters, one more route needs to be operated. At this time, we should choose a safer 5 meters for the retraction distance. Therefore, when there are obstacles on the boundary, the conservative solution can choose to shrink the spray width by one distance.

2 Retract distance in the boundary when barrier-free

When there are no obstacles on the border, many people think that it is most appropriate to shrink half the spray pattern within the border, just to spray the border. In fact, the field working environment is changeable. If there is a gust of wind during spraying, the indentation of half of the spray frame can easily cause leakage due to the wind. Therefore, when the boundary is barrier-free, the spray range can be set to be about 1 meter beyond the field boundary (without affecting the surrounding crops), which can reduce the leakage caused by the environment.

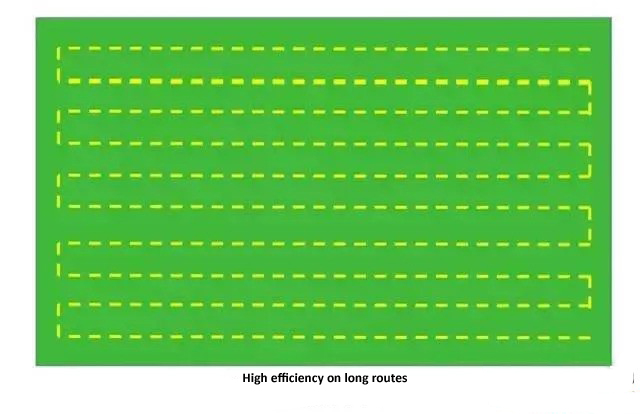

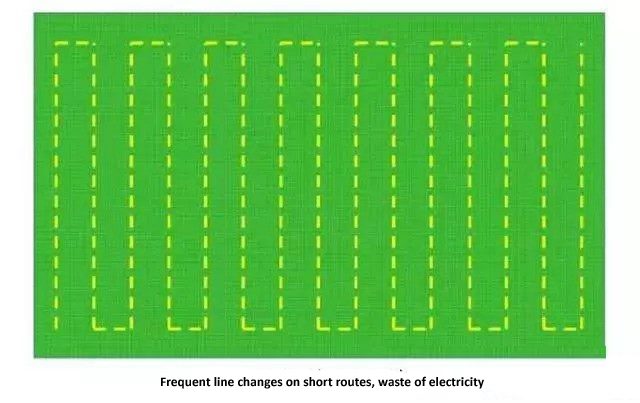

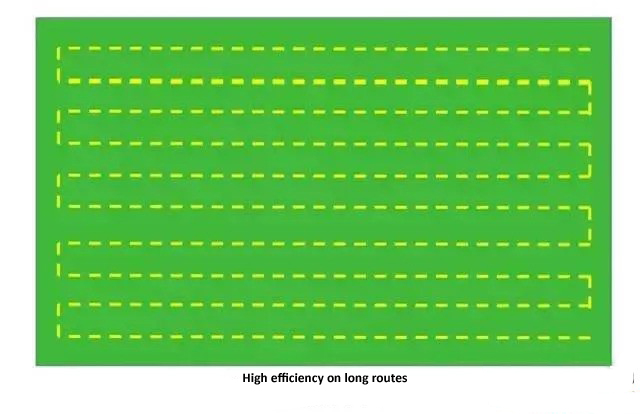

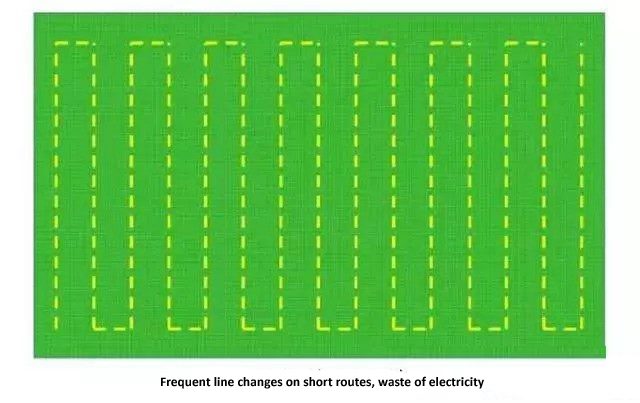

Long route planning

When planning a route, the longer the route, the better. As we all know, the process of plant protection aircraft operations is much slower than normal flight routes. Frequent line changes can lead to wasted time and power. Therefore, in order to improve operating efficiency and reduce operating costs, long-term routes should be the main focus when planning routes.

However, after testing, it was found that when the route length exceeds 200 meters, the improved efficiency is not obvious. For example, if a piece of land is 200 meters long and 400 meters wide, the efficiency of a 200-meter route and a 400-meter route are not much different. At this time, you can decide whether to fly a 200-meter route or a 400-meter route according to specific environmental factors.

However, after testing, it was found that when the route length exceeds 200 meters, the improved efficiency is not obvious. For example, if a piece of land is 200 meters long and 400 meters wide, the efficiency of a 200-meter route and a 400-meter route are not much different. At this time, you can decide whether to fly a 200-meter route or a 400-meter route according to specific environmental factors.

Slope route planning

1 Conventional slope operation route

When planning the slope operation route, the route should be set along the slope contour. When set as a conventional climbing route, the plant protection machine needs to consume more power than flat ground operations during the entire operation to complete the climbing and downhill, which will consume more electricity.

2 Contour line for slope operation

However, if the contour route is implemented, the route is similar to flying on flat ground, and it only needs to be raised and lowered during a short change of lane. Compared with the previous route operation method, it greatly improves the operation efficiency and reduces the risk of crashing.

How to set the height when working on slopes? Taking the contour line operation route as an example, if the line-changing and traversing distance of the plant protection machine is 5 meters, then we need to know how much the height of the slope has changed on the slope of the current operation by 5 meters.

If the plant protection machine moves horizontally by 5 meters and the slope height rises by 1 meter, the normal minimum working height is not less than 1.5 meters. To ensure the safety of the plant protection machine when moving horizontally, the minimum height should be set to 1+1.5=2.5 meters. In this way, each time the plant protection machine moves horizontally, there is a safety height of more than 1.5 meters as a buffer, which greatly reduces the chance of accidents.

How to set the height when working on slopes? Taking the contour line operation route as an example, if the line-changing and traversing distance of the plant protection machine is 5 meters, then we need to know how much the height of the slope has changed on the slope of the current operation by 5 meters.

If the plant protection machine moves horizontally by 5 meters and the slope height rises by 1 meter, the normal minimum working height is not less than 1.5 meters. To ensure the safety of the plant protection machine when moving horizontally, the minimum height should be set to 1+1.5=2.5 meters. In this way, each time the plant protection machine moves horizontally, there is a safety height of more than 1.5 meters as a buffer, which greatly reduces the chance of accidents.

Hybrid 16L Spraying Drone

Hybrid Crop Spraying Drone drone with 16L tank Quadcopter Drone long endurance spraying drone for agriculture

Hybrid Crop Spraying Drone features a gasoline + electric power system with great flight times and easy maintenance! This hybrid drone for crop spraying is portable thanks to folding arms and the modular design. The FD-416 crop dusting UAV can be used for any spraying missions – use it for agricultural, solar panel cleaning, roof spraying and anything else where a spraying drone would save you time and money! The FD-416 crop sprayer Hybrid is perfect for customers who don’t want to deal with battery charging or storage. This spraying UAV is also a great candidate for extreme cold or hot climates where drone batteries suffer.

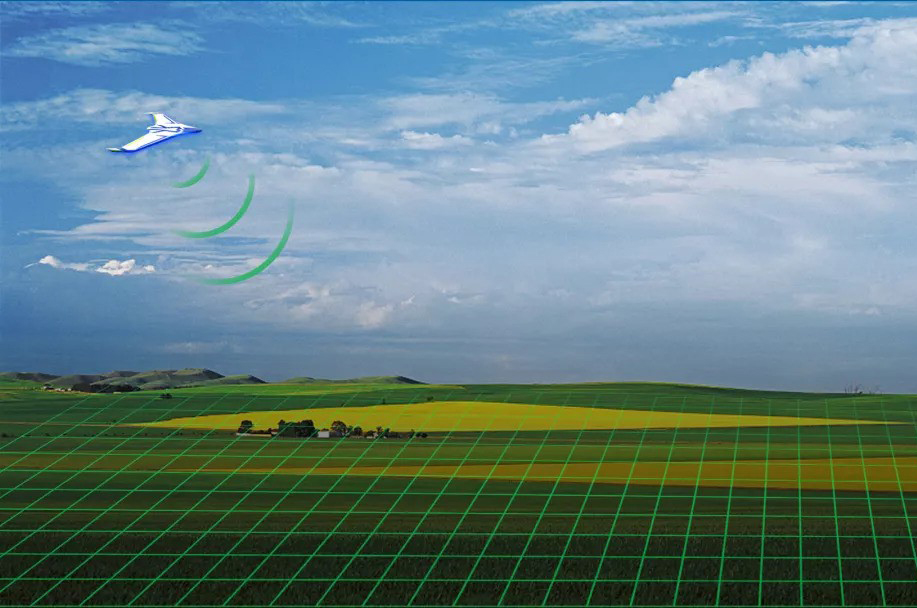

Using drones for agriculture increases the precision and efficiency with which farmers can work, and makes it easier to make informed land management decisions. Drones can be deployed for a wide variety of tasks, including monitoring of livestock and the health of crops, estimation of soil conditions, planting of future crops, and countering infections and pests.

This powerful propulsion system allows the UAV to carry up to 16 litres of liquid in total (including the fertilizer), with a maximum takeoff weight of 40 kg. The drone can therefore operate for longer and cover more farmland in a single flight, without the need for farmers to take heavy batteries out into the field.

Product description

Model:FD-416

Number of axes:4 axis

Wheelbase: 1500mm

Power : 6000w Hybrid power

Medicine box vol1ume:max 16L

Fuel tank capacity : max 3.5L

Hybrid model: FL6000W

Full load flight time: 45 minutes

Weight:

1. Full load takeof weight: 40KG

2. Frame weight: 4.45KG

3. Hybrid powver weight: 7.2KG

4. Flight power system assembly weight: 4 * 1.65KG

5. Medicine bax weight: 1.5KG;

6. Fuel tank weight: 0.56KG