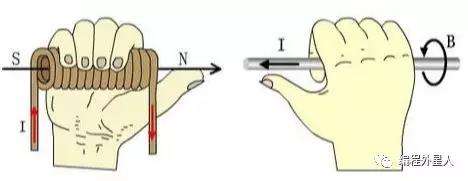

The principle of motor rotation seems simple today. Generally, the junior high school physics class will talk about the principle of motor movement. Let's review it together now. First of all, we know the Faraday electromagnetic principle. When a current passes through a wire, a magnetic effect is generated. According to the right-hand rule, the current flows in the direction of four fingers.

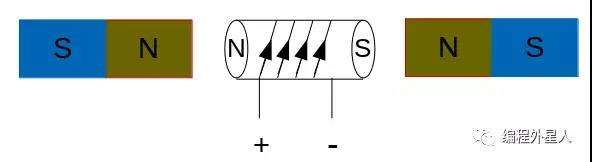

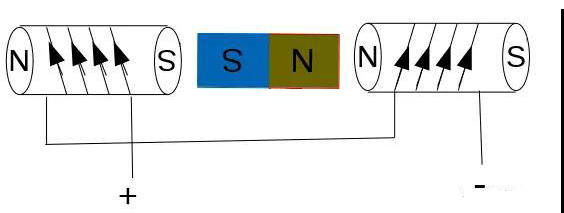

We will use an electromagnet as the device for winding an iron rod with a coil. When the coil is energized, the iron rod will produce magnetism. Due to the magnetic effect of the current flowing through the coil, according to the principle of homopolar repulsion and opposite attraction, if the core of the iron rod is added to a rotatable shaft and a permanent magnet is added to the outside, as shown in the figure below:

According to the principle of homosexual repulsion and attraction of the opposite sex of the magnet, the N pole of the electromagnet will be pushed by the permanent magnet N and the suction force of the permanent magnet S, so it will move clockwise, and the S pole of the electromagnet will also be moved. Repelled by the S pole of the permanent magnet and attracted by the N pole of the permanent magnet, it will also rotate clockwise. When the electromagnet rotates to 180 degrees, the permanent magnet and its force reach the maximum, so the electromagnet is at the 180 degree position. After a few swings it will stop in this position.

At this time, we hope that the electromagnet can keep rotating, so we naturally think of changing the direction of the current of the electromagnet, so that the original N pole of the electromagnet becomes the S pole, and the S pole becomes the N pole, so the electromagnetic The iron continues to rotate clockwise due to the action of the permanent magnet, and when we rotate 180 degrees again, we change the magnetic pole of the electromagnet. Therefore, every 180 degrees of the electromagnet changes the direction of the magnetic pole, so it will continue to rotate. This is what we call the principle of electrical machinery rotation.

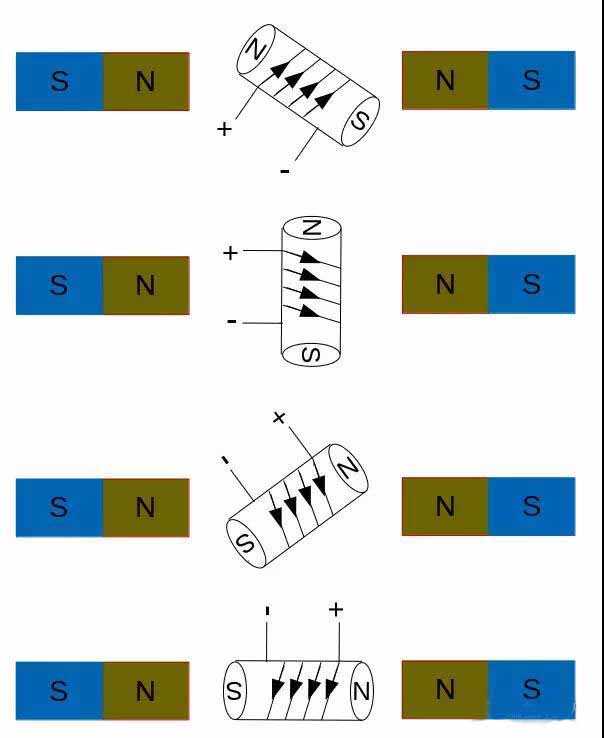

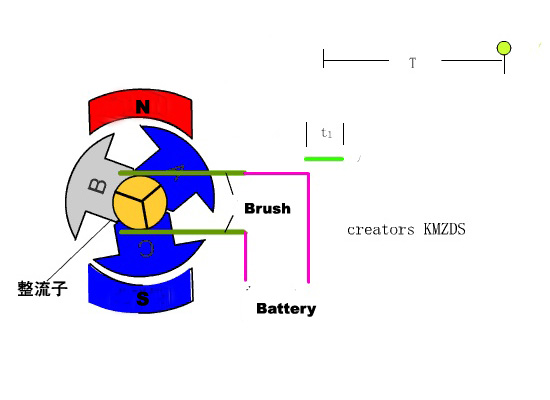

But there is a problem in this, how to make the electromagnet of the motor automatically change its current direction when it rotates to 180 degrees? In fact, this problem has been solved perfectly. Please look at the following diagram:

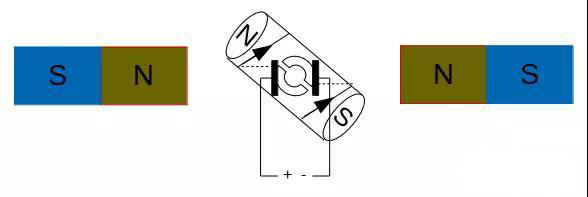

The dotted line in the figure above is the wire connecting the coil to the conductor sheet. This is the schematic diagram of a brushed motor. On the rotating shaft of the electromagnet inside the motor, install two semi-circular conductor pieces, and clamp two semi-circular conductors with two brushes on both sides of the conductor. On the other hand, when the electromagnet rotates through 180 degrees, the inertia will slightly turn by a small angle, exceeding 180 degrees. At this time, the position of the brush contacting the conductor sheet changes, that is, the positive and negative poles of the power supply change. The direction of the current changes, so the magnetic pole of the electromagnet and the permanent magnet will work together, and the electromagnet will rotate.

We call the continuously rotating part of the motor the rotor of the motor, and the stationary, fixed part is the stator of the motor. Generally, if the brush is rotated 180 degrees and the current direction is changed again, sometimes it will enter a dead angle at 180 degrees. So in most cases, the solenoid of the brushed motor is three sets of coils, and the brush has only one set. It can be turned under any circumstances, as shown below:

If you want to change the rotation direction of the brushed motor, just change the positive and negative poles of the motor power supply. For multi-rotor drones, small drones usually use brushed motors, such as hollow cup motors; while drones with large wheelbases, usually greater than about 200mm, use brushless motors. Let's take a look at the principle and composition of brushless motors together.

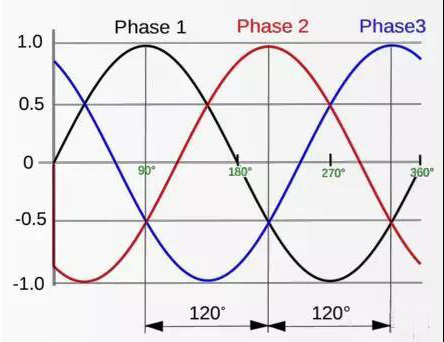

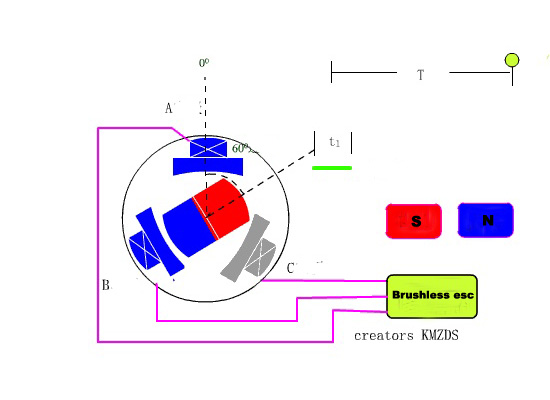

Because the electromagnet cannot rotate, it is necessary to generate different magnetic fields by changing the electric current of the electromagnet, so that the external permanent magnet is rotated. For a brushless motor, it can be controlled by a three-way bridge connection and two-on conduction. When the rotor of the motor rotates 120 degrees, the inverter switches the current once and the magnetic state of the stator changes once:

To change the direction of rotation of the brushed motor, just reverse any two of the three power cords. The rotating part of a brushless motor is a permanent magnet, also called a rotor; the non-rotating part is an electromagnet, also called a stator. The device that controls the electromotive force of a motor is called an ESC. We will learn the ESC control method in the next lecture.

There are several common indicators for quadcopter motor: stator height, stator width, and motor KV value. When we look at the motor parameters, we can see that the motor model will indicate 2212 2216 2312 and so on. The first two numbers indicate the diameter of the motor writing, and the last two numbers indicate the height of the motor stator. The units are millimeters. . For example, 2206 indicates that the diameter of the motor stator is 22mm, and the thickness of the stator is 6mm. 2312 indicates that the diameter of the motor stator is 23mm, and the height of the stator is 12mm. 2216 indicates that the diameter of the motor stator is 22mm, and the height of the stator is 16mm.

The index KV value indicates how much the motor's revolutions per minute increase when the voltage is increased by 1v under no-load (without propeller installed). The smaller the KV value of the motor, the greater the power of the motor, but the lower the speed; the larger the KV value, the smaller the power of the motor, but the faster the speed. You can imagine the gears of a car. The lower the gear (such as the 1st gear), the more powerful the engine, but the lower the speed; the higher the gear (such as 5th gear), the lower the engine's power, but the faster the speed. .

More details of quadcopter motor an drone parts, please visit droneassemble.com

More details of quadcopter motor an drone parts, please visit droneassemble.com

Contact: Fly Dragon Drone Tech.

Email: frank at dronefromchina.com

Add: NO. 9 Dayu Road PiDu distric, ChengDu 611730, China